Home / TFC

Double drum cutter heads

with continuous cutting

The TFC chain drumcutters (Simex patented) are specifically designed for mounting on mini-excavators and excavators up to 12 tons. Chain drum cutters feature an innovative system without gaps at centre or side footprints and are ideal for finishing flat surfaces and trenches. Quiet and precise in the work zone, they do not intrude on the surrounding area.

Versatile and high-performing, chain drum cutters can also be utilized for crushing roots and tree trunks, milling asphalt and cement, milling plaster.

Benefits

- VERSATILITY

- LOW NOISE

- CONTINUOUS CUT MILLING

- HIGH PRECISION

- NARROW AND DEEP EXCAVATIONS

| TECHNICAL DATA | °°° | TFC 50 | TFC 100 | TFC 400 | TFC 600 |

|---|---|---|---|---|---|

| Recomm. excavator weight (1) | ton |

1,2-3 |

2,5-4,5 |

6-10 |

9-12 |

| . | lbs |

2640-6600 |

5600-9900 |

13000-22000 |

20000-26400 |

| Weight without bracket | kg |

90 |

170 |

400 |

670 |

| . | lbs |

200 |

375 |

880 |

1470 |

| Width (cutting profile) | mm |

370 |

480-430(*) |

500-440(*) |

540-490(*) |

| . | inch |

15 |

19-17(*) |

20-17(*) |

21-20(*) |

| Drum diameter (cutting profile) | mm |

230 |

260 |

420 |

480 |

| . | inch |

9 |

10 |

16 |

19 |

| Max. required oil pressure (2) | BAR |

250 |

300 |

300 |

300 |

| . | psi |

3625 |

4350 |

4350 |

4350 |

| Required oil flow (3) | l/m |

20-40 |

30-60 |

65-115 |

90-150 |

| . | gpm |

5-10 |

8-16 |

17-30 |

24-40 |

(*) Narrow drums for increase penetration.

(1) User is responsible for ensuring that the equipment meets the excavator's specifications and weight requirements.

(2) Torque and cutting force decrease with lowered operating pressure.

(3) RPM and cutting speed decrease with lowered oil flow.

Simex does not accept responsibility or liability for the information provided. Technical modifications may vary without prior notice.

These are the standard features, for custom solutions don't hesitate to contact us.

FEATURES

The whole range consists of 4 models, TFC 50 and TFC 100 for mini-excavators between 1.2 and 4.5 tons, and TFC 400 and TFC 600 for excavators between 6 and 12 tons.

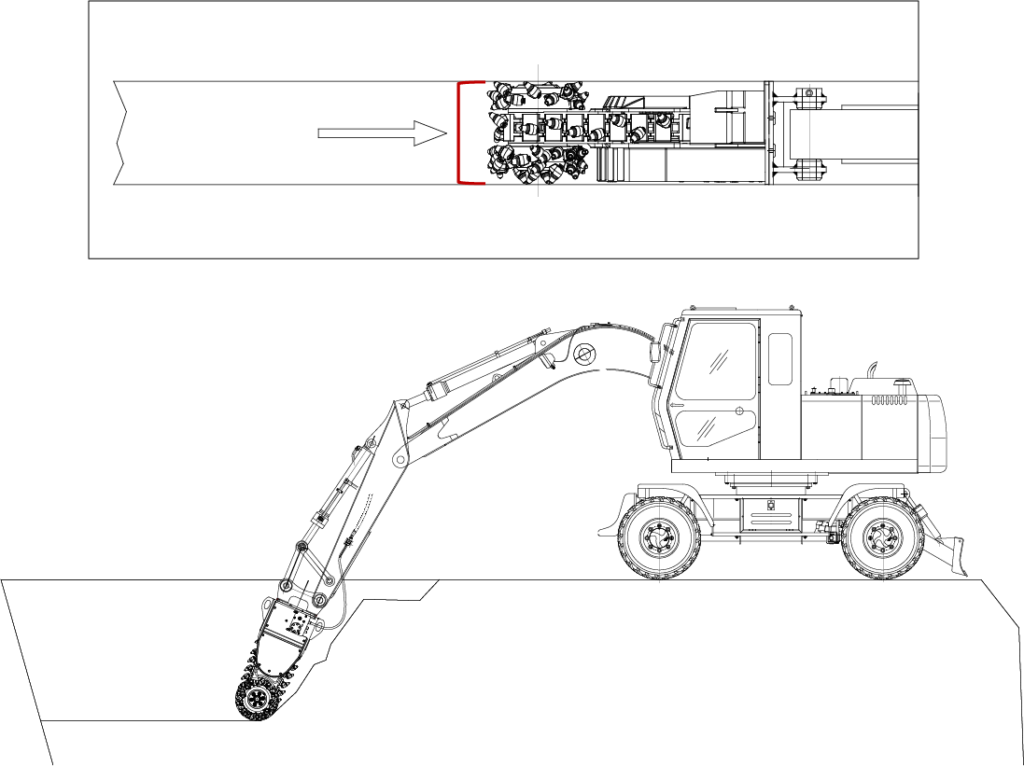

CONTINUOUS CUTTING WITH CENTRAL CHAIN

TF technology is naturally completed by the TFC range, chain drumcutters for excavators in the 1.2-12 ton category. It features a double drum system plus central chain, which makes the front continuous cutting profile without gaps at centre between the drums. Ideal for finishing flat surfaces and for creating set-section trenches.

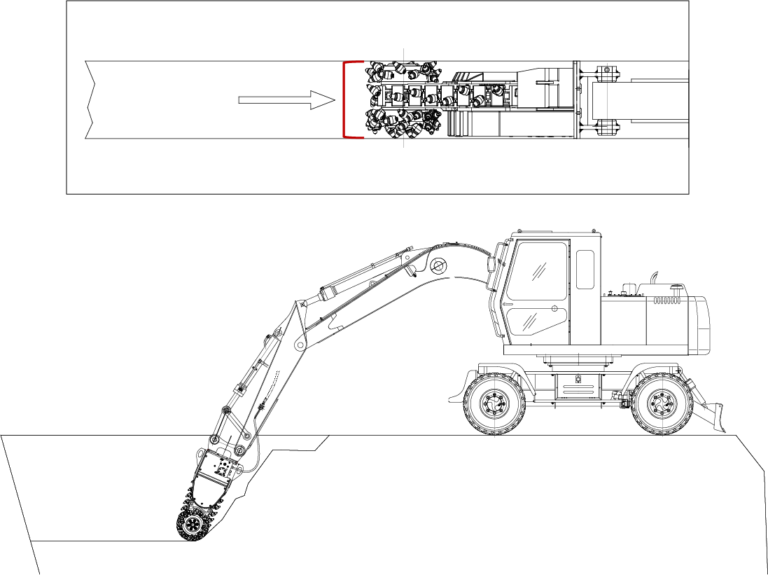

TRENCHING

With trench excavations it is possible to work at theoretically infinite depths (the only limit being the excavator boom) since thanks to the continuous cut given by the central chain, the operator’s movement will only be vertical, without the need for a second cutter on the side.

In trench excavations, the continuous cut thus allows the operator to keep the excavation width as small as possible: the latter corresponds to the cutting width of the cutter head. This translates into time savings and increased hourly productivity.

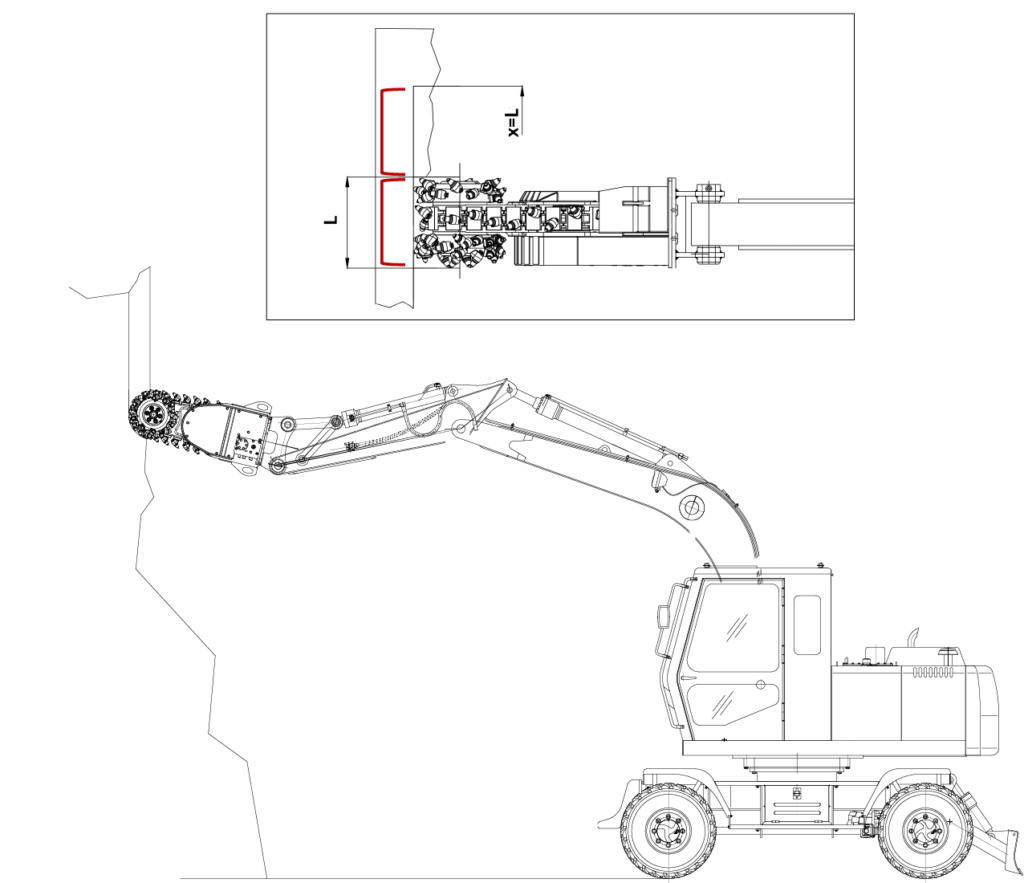

Wall profiling

Similarly to plane surfaces, with the TFC is possible to do narrow millings of the same width of the chain cutter head profile on vertical walls or tunnel vaults; chain drumcutters are particularly indicated for laying utilities, building elements, formworks etc.

The continuous cut technology is fundamental profiling walls and tunnels, since the side-by-side passes with the entire cutting width profile (L) avoids any unmilled material to be left between a pass and the other. The increased milled material (X) grants more productivity in less time.

SIDE WHEELS

The option of fitting the attachment with SIDE WHEELS (only for models TFC 50 and TFC 100) grants perfect control on the thickness of the milled material, as occurs in the selective removal of plaster on vertical walls.

HIGH PERFORMANCE AND GREAT VERSATILITY

Quiet and precise in the work area, TFC chain drumcutter's versatility ensures high performance in various application fields:

- Profiling of tunnel vaults, foundations and concrete surfaces

- Milling of bituminous conglomerate and concrete

- Milling of plaster (the side wheels grant perfect control of the thickness removed)

- Crushing of roots and tree trunks

- Trench excavation

APPLICATIONS

UTILITIES

The TFC chain drum cutter is designed for interventions where the accuracy of the excavation geometry is combined with productivity data. In trench work for laying utilities, the width of the excavation corresponds to the width of the cutter head, thus maintaining a narrow and deep section.

BUILDINGS AND INFRASTRUCTURE

The TFC chain drumcutter plays a major role in profiling vertical walls in the construction field and infrastructure. The side-by-side passes, which take advantage of the entire cutting width, remove more material and ensure substantial time savings.

Quiet and precise in the work area, as well as on asphalt and cement, the TFC chain drum cutter is often used to mill plaster from walls, with the option of fitting side wheels which grant perfect control on the thickness removed.

tunneling

The accuracy and precision in the work area, as well as the low vibrations, make chain drumcutters with continuous cutting excellent attachments for tunneling work, as an alternative to conventional systems that are often too invasive and more expensive.

The large cutting surface of the TFC chain drum cutters is particularly suitable for profiling vertical and inclined walls, as is the case for tunnel vaults. The selective removal of deteriorated concrete for later remediation is one of the fundamental activities in the maintenance of tunnels, to ensure proper viability of high-traffic roads.

RICHIEDI INFORMAZIONI

I campi contrassegnati con asterisco (*) sono obbligatori.

A problem was detected in the following Form. Submitting it could result in errors. Please contact the site administrator.